SOCAR

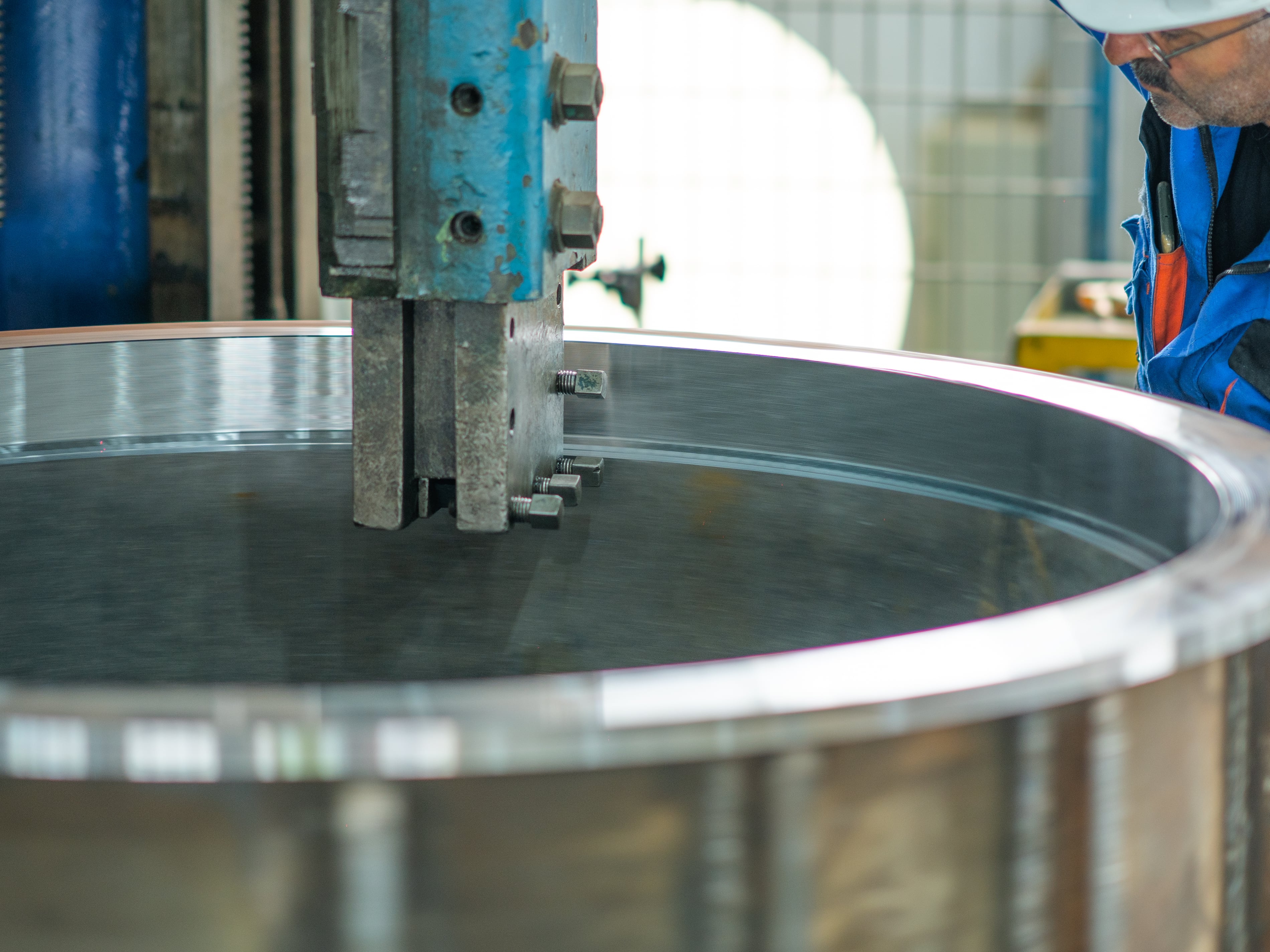

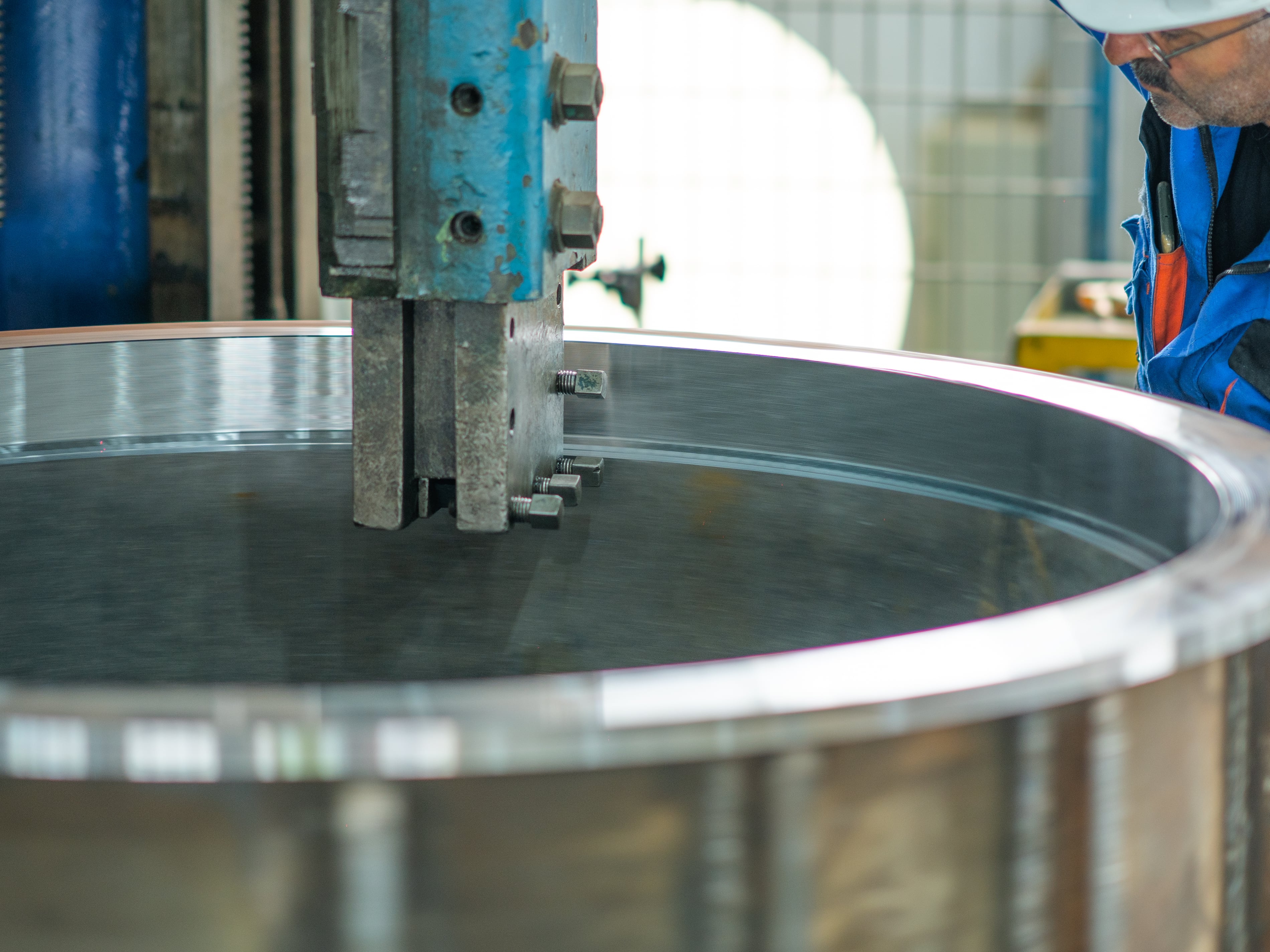

Test RingWESA successfully completed the manufacturing of 39 high-flexibility test fixtures for heat exchangers, commissioned by SOCAR Downstream Management. A total of 200 tons of structural steel was utilized to produce these fixtures, which were designed to meet SOCAR’s rigorous technical and operational requirements.

Each fixture was custom-engineered to ensure maximum performance, reliability, and compatibility during heat exchanger test processes. The production faced significant timing constraints as the technical drawings could only be finalized after the exchanger covers were opened and maintenance activities completed. Despite this, all fixtures were delivered within the strict 8-day production window per unit.

Scope Highlights:

-

Design and fabrication of 39 custom high-flexibility test fixtures

-

Utilization of 200 tons of steel

-

Project delivery aligned with SOCAR’s strict operational deadlines

-

Overcoming limited design timeline and post-maintenance manufacturing constraints

Client: SOCAR Downstream

Location: Azerbaijan

Duration: 8 days per unit following final design approval

Other projects

SOCAR EP 300

Turbine Building